Raising the bar on PFAS removal

BY MARIA STRANNE

In 2018 alone, about 25,000 tonnes of PFAS were released into the atmosphere, soil and water.

Highly stable and resistant to degradation once in the environment, PFAS is a large group of manmade chemicals, known as ‘forever chemicals’. As the chemicals are being linked to several serious health problems in humans, including cancer, thyroid disease and immune system disorders, the removal of PFAS from water sources is becoming increasingly urgent. Writing for Discover Cleantech, Maria Stranne, PhD in biotechnology, explores the problem and its solutions.

PFAS, or per- and polyfluoroalkyl substances, are a group of more than 4,700 man-made chemicals, including fluorine-containing compounds, such as PFOS, PFOSA, and PFOA. As the total number of PFAS substances released into the environment has been rising since the early 2000s, addressing the issue is becoming increasingly urgent. In 2018 alone, about 25,000 tonnes of PFAS were released into the atmosphere, soil and water. Even rainwater in the Himalayas and Antarctic contain unsafe levels of PFAS, according to recent studies published from Stockholm University and ETH Zurich.

With concerns about the potential health risks associated with PFAS continuing to increase, new legislations addressing the issue are being proposed all over the world, and scientists are researching and developing new technologies to help reduce human exposure to the chemicals. These technologies include advanced filtration systems, new materials and more sustainable methods of manufacturing without, or with reduced, PFAS.

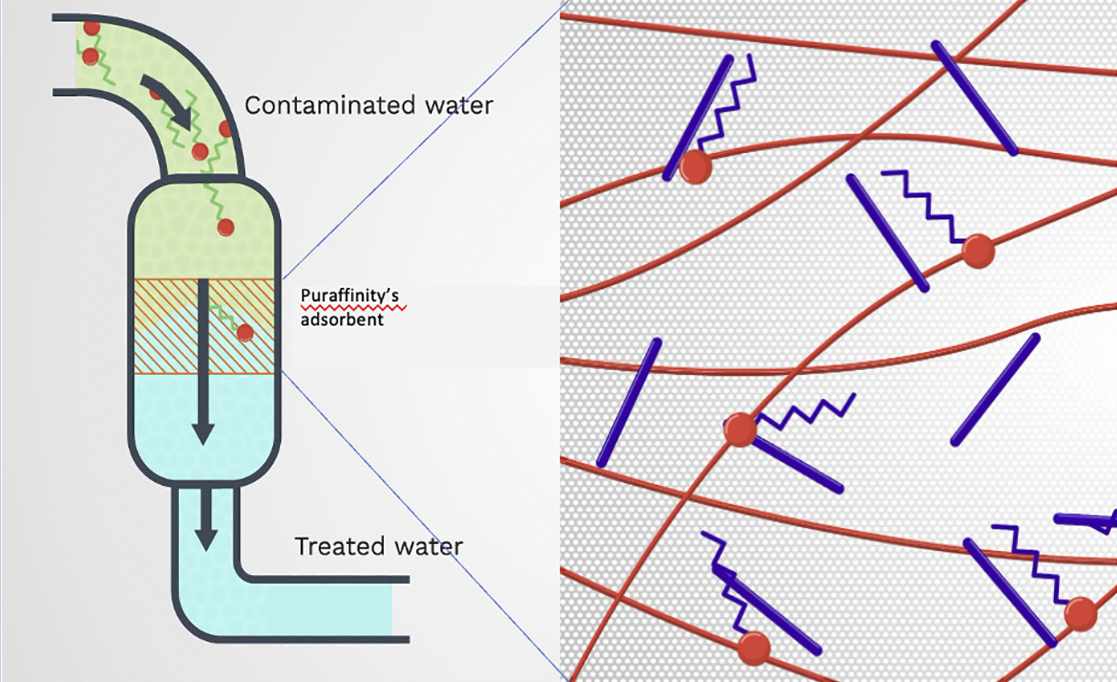

Among the new innovations is a technology from the London-based science-materials company Puraffinity, which promises to remove PFAS from water sources more efficiently and at a lower cost than existing solutions. The technology utilises a special type of resin that attaches to the PFAS molecules retaining them from the water. The resin can then be cleaned and reused, making the process both cost-efficient and sustainable.

Henrik Hagemann, CEO and co-founder of Puraffinity, welcomes the stricter regulations on PFAS, as he believes it will enhance the competitiveness of their products.

Stricter regulations

Since their development in the 1940s, PHAS have been used in a variety of industrial and consumer products and are known for their non-stick, waterproof and heat-resistant properties. In domestic products they are everywhere, from car and floor polish, textile and fabric treatments to food packaging, cookware, cupcake forms and skin cream. In the industry too, they are used in a wide range of products, including firefighting foam, semiconductors and space suits, making them an important pillar in society.

At this stage, the regulatory framework for PFAS is constantly being revised; currently, new legislations are being proposed in the EU, USA and UN to minimise outlet and usage.

Henrik Hagemann, CEO and co-founder of Puraffinity, welcomes the stricter regulations on PFAS, as he believes it will enhance the competitiveness of their products.

The Puraffinity adsorbent materials deliver high selectivity and fast kinetics, and according to Henrik Hagemann: “The fast kinetics of Puraffinity’s media means that water and wastewater industries can do more with less – they can increase the treatment capacity of an existing plant to fulfill new legislated requirements to treat PFAS to lower levels, without needing to expand their treatment plant, which means CapEx savings. This combination maximises the water treatment performance and amplifies the spectrum of unwanted substances removal, allowing customers to get sustainable removal of PFAS at the lowest Total Cost of Ownership.”

The Puraffinity absorbent material has the potential to be used in a wide range of products, such as small pitcher-type filters and large steel tanks or vessels for industrial applications.

According to Puraffinity, the fast kinetics of its media means that wastewater industries can fulfill new legislated requirements to treat PFAS to lower levels, without needing to expand their treatment plant.

Cleaning the world’s water supply

While nearly all of us have some level of PFAS in our bodies today, the highest concentrations of PFAS have been found in the blood serum of people living or working near manufacturing, industry or disposal sites, with some concentrations being up to ten times higher than the general population, as stated in a report from the European Environment Agency. Although several studies have been published about PFAS exposure and health effects, it is difficult to link PFAS directly to health conditions in humans. Since the majority of the linked diseases have long latency periods, the negative health effects of exposure are often seen after many years of accumulation in the body. However, increasing amounts of evidence is coming to light and one group of PFAS, the PFOS (restricted in Europe for more than ten years), has been proven to have a negative effect on reproduction and to be linked to immune system disorders and hormonal disturbances.

Thus, as chemical build-up in humans continues to increase, removing PFAS from water and preventing more from being let into the environment is crucial.

Currently, solutions to remove PFAS from water sources include filtration systems placed in wastewater plants and near industry sites. Most systems rely on ionic interactions, Granulated Activated Carbon or petroleum-derived Ion Exchange, but these methods are nonspecific and have trouble binding smaller PFAS, as well as other pollutants. The solution developed by Puraffinity utilises a combined mechanism of ion exchange and adsorption to bind PFAS. According to Henrik Hagemann: “Puraffinity’s material binds PFAS compounds preferentially over other contaminants present in water, even in the presence of co-contaminants at 10^5 higher concentrations, because we have tailored the surface of our materials at the molecular level.” Frequent replacement of filtration materials in treatment plants can be a logistical challenge, adding additional stress to plants that are already facing external factors, such as increased storm surges and rising sea levels due to climate changes.

Puraffinity’s products, on the other hand, have been developed to be reusable, explains Henrik Hagemann. “Once all the Puraffinity material is filled up with PFAS, the material is engineered to unclick the bound PFAS using a safe regeneration step. The Puraffinity material can then be re-used for non-point-of-use applications, like industrial or environmental remediation, enabling a circular economy for the future of water filtration materials.” This is a huge advance in comparison to previously-used methods. Finally, recent studies have demonstrated the effectiveness of the Puraffinity material in removing PFAS chemicals to levels well below the current regulatory threshold. Trials were undertaken at two independent institutions in the USA – the Water Hub at Colorado School of Mines and at the Heritage Research Group. They showed the material can remove PFAS to below the 10 ppt (0,01ng/L). This highlights the potential of the technology, combined with stricter regulations, to significantly improve the chances of lower PFAS levels in the water supplies of future generations.

The water treatment technology from Puraffinity utilises a special type of resin that attaches to the PFAS molecules retaining them from the water.

Subscribe to Our Newsletter

Receive our monthly newsletter by email