Coffee grounds – keeping your shirt fresh and your home warm

BY KARIN BLAK

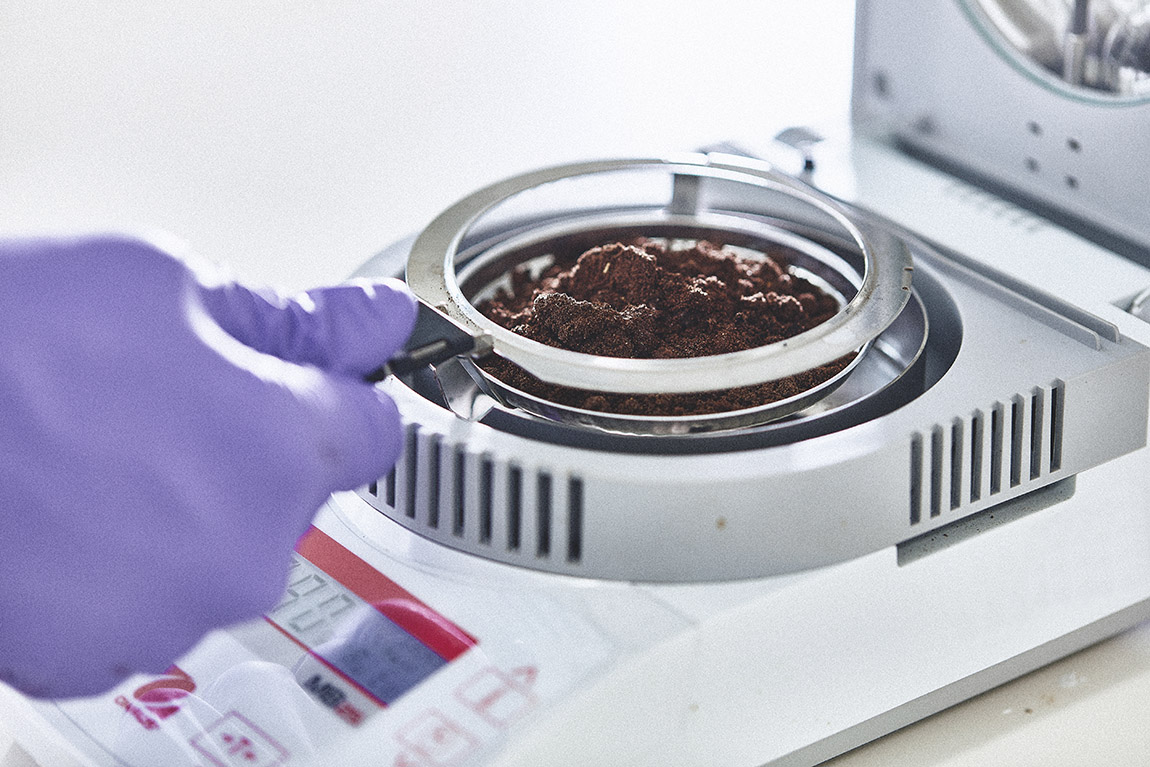

The process starts by cleaning and drying the soggy SCG. Photo: bio-bean

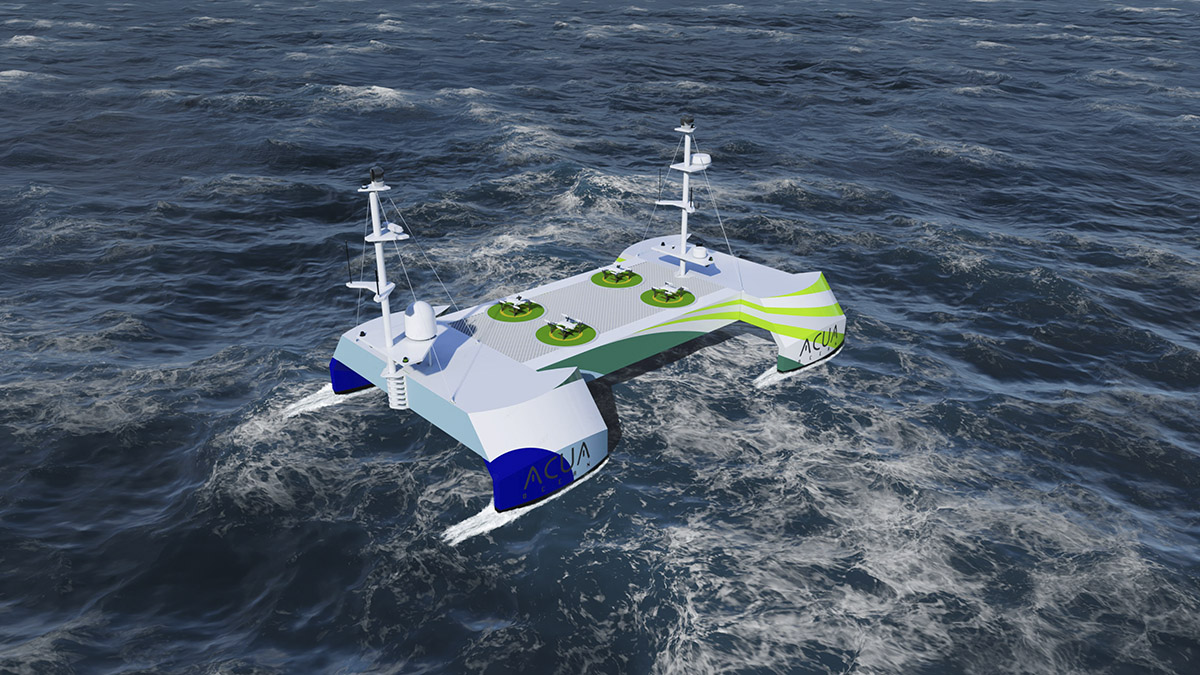

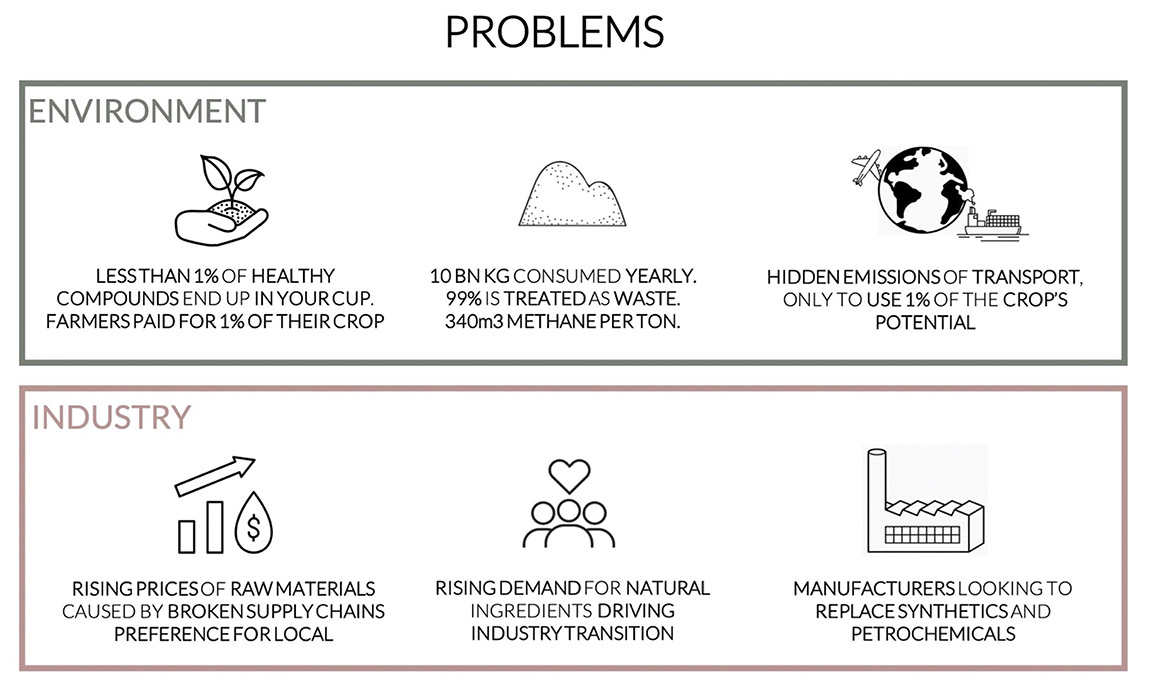

From flavourings to brake pads and soil conditioners – spent coffee grounds (SCG) have multiple uses, and with approximately one billion kilos of coffee beans produced yearly, the potential is immense. Consequently, researchers and businesses are looking at utilising the potentials of this by-product across a wide spectrum of industries.

In 2020/21, approximately one billion kilos of coffee beans were produced worldwide. That is an increase of about 80 per cent over the previous ten years, and with the popularity of coffee, this rise in production is set to continue. However, only one per cent of the actual bean is used when making a cup of coffee. This leaves 99 per cent as spent grounds going into landfill, often in a plastic bag.

The profits from the sale of coffee logs and pellets supports the research into better ways of using SCG. Photo: bio-bean

Here, the oxygen-free environment provides the perfect conditions for anaerobic bacteria to break down the grounds. All well and good, but this natural breakdown process releases methane into the atmosphere, which is 30 times more potent as a greenhouse gas than CO2.

As such, SCG provide the perfect example of how including a waste product in a circular economy can save money for businesses, cut down on greenhouse gas emissions, and produce sustainable, natural products.

Once oil has been extracted, the dry grain that is left has many uses. Photo: bio-bean

Evading the landfill

The company bio-bean in the UK is collaborating with existing waste management groups to collect SCG from nationwide coffee chains, independent coffee shops and restaurants, office blocks and more. Jessica Folkerts, head of marketing at bio-bean, says: “Rather than sending out a separate bio-bean truck to collect the SCG, using an existing service saves energy and cuts emissions, plus collecting directly from businesses saves them millions in disposal fees.”

Preparing the spent, wet grounds is relatively straightforward, Jessica explains; first removing anything that does not belong, followed by the drying process which can also sterilise the grounds. Then comes the oil extraction phase and treatment of the leftover grounds depending on the industry the end product is intended for.

Coffee fibre is used in bread making. Photo: Kaffe Bueno

Snack bars and face scrubs

Coffee oil is a product that is used in both the food and the beauty industries. The oil extracted from SCG provides rich and natural coffee flavouring and is also a preservative. Perfect for the food and beverage industry.

When used in the beauty industry, coffee oil’s protective components are said to be excellent for use in sun-care creams, while the caffeine is perfect for anti-ageing treatments and anti-cellulite formulations.

Kaffe Bueno in Denmark has taken the science one step further. Once the oil, and with it the majority of the coffee flavour, has been extracted, what is left is a fibre which is milled into a fine powder.

This is a caffeine-free, low fat, rich in protein and potassium, insoluble dietary fibre, and what is more, it is gluten free. Kaffe Bueno supplies the food industry with this sustainable product for use in baking and confectionery, pizza and pasta, and healthy snack bars. They state that the profile of this fibre “comprises nutty and chocolate notes. Although it comes from coffee, its coffee taste is mostly gone along with the oil extracted.”

The beauty industry is making good use of these fibres too. It’s naturally abrasive in texture and is used in scrubs, masks, soaps and cleansers, replacing plastic grains where they previously were used.

Coffee fibres are even used in the making of pizzas. Photo: Kaffe Bueno

Cutting costs and carbon emissions

Even the clothing industry is finding SCG a useful product. The #rens clothing and shoe company states that they use antimicrobial coffee fibre in their clothing and shoes to fight unwanted odours, helping the wearer to “stay forever fresh and wash less”.

The possibilities of SCG-based products seem endless. Bio-bean’s coffee logs and pellets replace wood and though it has a similar CO2 output to wood when burned, Jessica Folkerts notes that it may have a smaller overall carbon footprint, depending where and how the wooden logs have been sourced.

The problems SCG can help to solve. Photo: Kaffe Bueno

Bio-bean is turning SCG into a consistent, sustainable raw substance known as Inficaf, to replace the need for virgin or synthetic materials. This base product is used, for example, in the making of brake pads in the automotive industry and, appropriately, in the production of front covers of convenience coffee machines.

Taking things one step further, researchers around the world are exploring the use of SCG as aggregates in the construction industry, and the use of coffee oil in a more sustainable plastic production.

99 per cent of SCG go to landfill. Photo: bio-bean

An uplifting example of a circular economy

The concept of a circular economy has been around for hundreds of years. Examples exist in the collecting of animal bones from households for use in bone China or the collection of human waste for use as fertiliser. Both formed part of the subconscious cultural thinking of the time.

The difference in today’s circular economy is the conscious change in cultural awareness of the damaging effect of waste. Taking action on waste, the European Parliament is updating its legislation on waste management and promoting a circular economy that reduces waste to a minimum. The European Parliament’s aim is that “when a product reaches the end of its life, its materials are kept within the economy wherever possible”. This principle certainly applies to SCG.

It takes open and naturally curious minds to explore the possibilities where none have been considered before. With an ever-increasing amount of SCG available, passionate researchers and businesses are reaching across the continents in collaboration to harness the full potential of SCG while growing the circular economy, with significant benefits to the planet.

Kaffe Bueno supply coffee fibre to bakeries. Photo: Kaffe Bueno

Subscribe to Our Newsletter

Receive our monthly newsletter by email