Innovative 100-in-five battery set to be produced in Italy by 2024

BY JASON DEIGN. ADDITIONAL TEXT BY SIGNE HANSEN

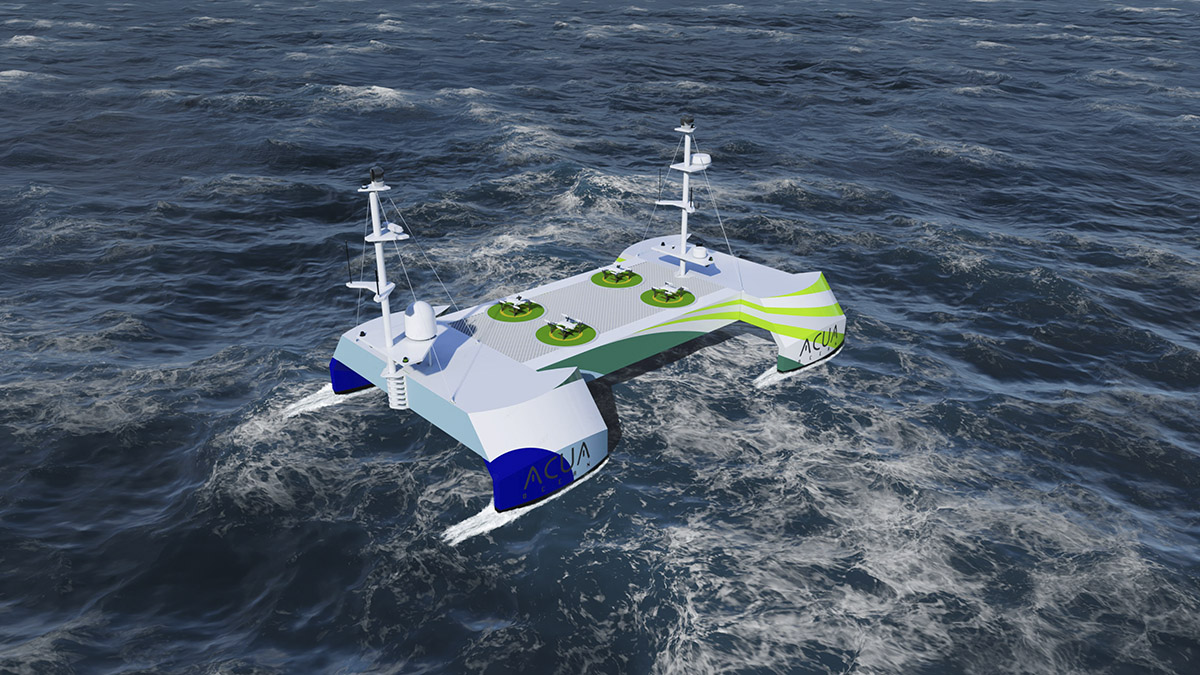

Set to be the largest battery factory in Italy, The Italvolt facility is set to manufacture a new battery developed by StoreDot, which can be filled up with 100 miles of charge in five minutes. Photo: Itavolt

The eradication of ‘charging anxiety’ has come closer thanks to an agreement between the Israeli battery developer StoreDot and manufacturer Italvolt. StoreDot, which plans to release an electric-vehicle battery that can fill up with 100 miles of charge in five minutes by 2024, has licenced its technology to Italvolt, which has plans to manufacture the products at a plant in Italy.

The Italvolt facility will be the largest battery factory in Italy and “will be crucial for us securing European manufacturing capacity,” says StoreDot’s chief executive, Doron Myersdorf.

Once StoreDot achieves its aim of mass producing a battery that can take 100 miles of charge in five minutes, it plans to cut charge times to three minutes by 2028 and two minutes by 2032. The company is focused on developing extreme-fast charging (XFC) batteries, batteries with ‘extreme’ energy densities, which are more efficient and longer lasting than today’s products.

“Our advanced 100-in-five technologies will eradicate charging anxiety, which is currently the biggest barrier to widespread electric vehicle ownership,” Myersdorf says. “We are excited to be forming this strategic collaboration with Italvolt, a company that shares our ambition for the entire battery ecosystem.”

Italvolt’s Italian manufacturing facility will be technology agnostic and use a modular production process allowing it to accommodate other battery technologies alongside StoreDot’s XFC fast-charging products, as well as upgrading processes to meet changes in XFC’s specifications. The agreement between Italvolt and StoreDot is seen as key to helping Italy create a modern, electric-vehicle based automotive industry that generates skilled jobs.

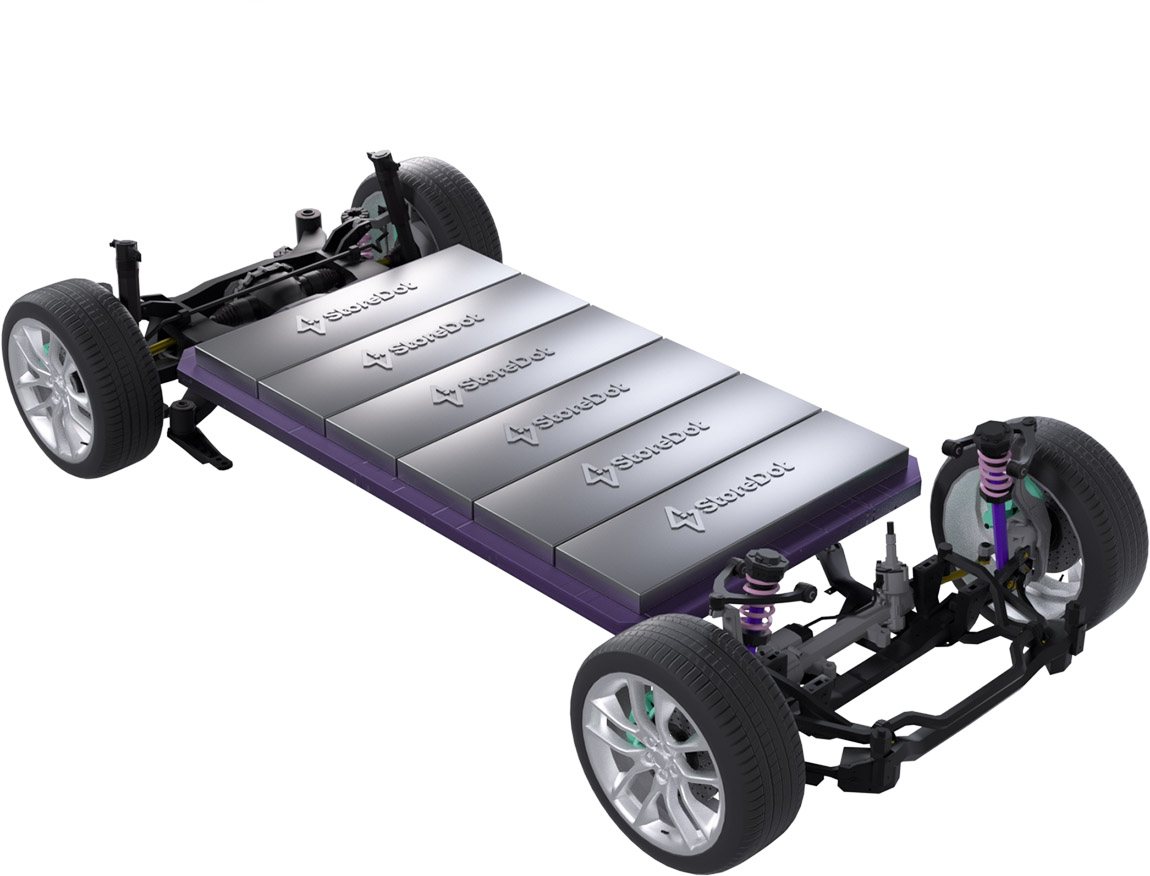

StoreDot’s 300 Wh/kg EV form factor pouch cells achieve over 1,000 consecutive extreme fast cycles, while guaranteeing auto makers no battery degradation due to extreme fast charging. Photo: StoreDot

Manufacturing capacity

The collaboration includes an offtake agreement enabling StoreDot to purchase Italvolt’s batteries for its own business and customers once production is complete. The Italvolt facility is scheduled to open in 2025 and will employ around 3,000 people, with sufficient manufacturing capacity to make 45 GWh of batteries a year. In October 2022, Italvolt appointed Bosch executive Joerg Klingler to speed up the development of the plant.

“Our collaboration with StoreDot is an inflection point in our journey to deliver high-quality lithium-ion battery cells at scale,” says Lars Carlstrom, Italvolt’s founder and chief executive. “Italvolt’s technology-agnostic, modular approach to production will ensure that we remain at the forefront of the industry as battery cell technology advances.”

European countries are scrambling to build electric vehicle manufacturing capacity, which is currently dominated by Chinese providers, but the path to creating so-called gigafactories is not always easy. In the UK, for example, the manufacturing hopeful Britishvolt went into administration in January 2023, laying off 232 employees and shelving plans for a massive electric car battery factory in Blyth, Northumberland.

The collapse has left a question mark over where the UK will get batteries for automotive manufacturers such as Jaguar Land Rover. With Britishvolt’s demise there is only one active gigafactory development in train in the country, which will supply up to 38 GWh of battery capacity for Nissan in Sunderland.

The StoreDot technology

Independently verified by the leading battery lab Shmuel De-Leon Energy in December 2022, StoreDot XFC battery technology was described as a “breakthrough and game changer for the automotive industry”. The battery, which is currently tested by over 15 global automotive brand manufacturers, has reshaped the conventional Li-ion battery by designing and synthesising proprietary organic and inorganic compounds optimised by Artificial Intelligence algorithms. The reduction in charging time is achieved primarily by replacing graphite in the cell’s anode with metalloid nano-particles, such as silicon, to overcome major issues in safety, cycle life and cell swelling during the charging process.

The battery tech has been in development for four years and is backed by patents in cell design, software and a self-repairing system that allows batteries to regenerate while in use.

With its 100-in-five technologies, StoreDot hopes to eradicate charging anxiety, which is currently the biggest barrier to widespread electric vehicle ownership, says chief executive, Doron Myersdorf. Photo: StoreDot

THE STOREDOT TECHNOLOGY Independently verified by the leading battery lab Shmuel De-Leon Energy in December 2022, StoreDot XFC battery technology was described as a “breakthrough and game changer for the automotive industry”. The battery, which is currently tested by over 15 global automotive brand manufacturers, has reshaped the conventional Li-ion battery by designing and synthesising proprietary organic and inorganic compounds optimised by Artificial Intelligence algorithms. The reduction in charging time is achieved primarily by replacing graphite in the cell's anode with metalloid nano-particles, such as silicon, to overcome major issues in safety, cycle life and cell swelling during the charging process. The battery tech has been in development for four years and is backed by patents in cell design, software and a self-repairing system that allows batteries to regenerate while in use.

Subscribe to Our Newsletter

Receive our monthly newsletter by email